Backorders can be both a challenge and an opportunity for growing businesses. A backorder happens when an item is temporarily out of stock but still available for purchase, with fulfillment expected once inventory is replenished. If managed properly, backorders allow you to continue generating revenue during high-demand periods or supply delays. However, poor backorder handling can lead to customer frustration, negative reviews, or canceled orders. This article explains what causes backorders, how to communicate clearly with customers, and how to implement a strategy that protects both your revenue and reputation.

Key Takeaways

- Backorders are for items that are not in stock but can be ordered with a guaranteed future delivery date, while out-of-stock items cannot be purchased at all.

- Common causes of backorders include supply chain disruptions, unexpected surges in demand, and inadequate safety stock.

- To minimize backorders, businesses should focus on accurate demand forecasting, maintain safety stock, set reorder points, and diversify suppliers.

Defining Backorders

The term backorder refers to orders for items that are not currently in stock but are promised to be fulfilled when they become available. Essentially, a backorder indicates that the demand for a product exceeds what the Seller has produced or currently holds in inventory. This often happens when demand surpasses supply, leading to a situation where customers can still place orders for items that will be shipped at a future date.

When a customer places an order for a backordered item, they are generally provided with a future ship date or ship date range, which is when the item is expected to be back in stock. This means that although the product is not available for immediate shipment, it is guaranteed to be delivered within a specified timeframe. For instance, if a customer orders a pair of shoes that are not in stock but are expected to arrive in two weeks, the order is placed on backorder.

Orders containing backorder items cannot be packed and shipped immediately. They may be split if other items in the order are in stock, leading to partially backordered items. When orders are split, the missing items should be clearly marked on the packing slip as being backordered.

Common causes of backorders include unexpected surges in demand, such as those triggered by viral trends or seasonal spikes. Understanding these dynamics helps businesses manage their inventory more effectively and maintain customer satisfaction.

Backorders vs Out of Stock

Differentiating between backordered and out-of-stock items is important for both businesses and customers. As discussed, backordered items are those that customers can still purchase, with the promise of future delivery. In contrast, out-of-stock items are unavailable for purchase until they are restocked. This distinction means that while backordered items provide a clear restock date, out-of-stock items do not offer such guarantees, and replenishment may never happen.

Backorders allow businesses to maintain a connection with their customers even when stock is depleted, but known future quantities are available. Customers who order backordered items are assured that their purchases will be fulfilled, fostering trust and continued engagement. Conversely, labeling items as out of stock can deter potential sales and weaken customer loyalty.

Deciding whether to classify a product as backordered or out of stock depends on factors such as customer patience and sourcing capabilities. Understanding this difference helps businesses optimize their inventory management and meet customer demand more effectively.

Common Causes of Backorders

Backordered inventory typically arises from various factors, including:

- Supply chain disruptions, such as adverse weather conditions or manufacturing delays

- Unusual spikes in customer demand

- Inadequate safety stock

- Supplier or raw material issues

The following subsections will delve deeper into why backorders occur, providing insights into how unexpected demand, low safety stock levels, and supplier problems can lead to backorders.

Unusual Demand

Unusual demand can lead to backorders, particularly when it is sudden and unexpected. Common causes of such surges include seasonality, media exposure, celebrity/influencer endorsements, and new marketing channels. For instance, a successful marketing campaign can trigger significant spikes in product demand, outpacing the available supply when demand exceeds supply.

Sales or promotions can also create sudden increases in customer demand, for example, landing a spot on Good Morning America’s Deals and Steals segment. However, if these spikes are not accurately forecasted, they can result in backorders as the supply may not meet the sudden increase in customer requests.

Low Safety Stock

Mismanagement of inventory levels can result in inadequate safety stock, contributing to backorders. Even with normal demand, miscalculating safety stock levels can lead to backorders. Insufficient stock levels due to improper preparation or counting can cause backorders.

Maintaining appropriate safety stock levels is essential to prevent backorders and meet customer demand. Effective inventory management involves keeping a buffer of safety stock to cover unexpected demand and supplier issues.

Supplier Issues

Manufacturer or supplier problems can result in backorders. These supply chain issues can manifest as delays in shipping or shortages of raw materials needed for production. Utilizing multiple suppliers can help maintain consistent inventory levels and mitigate supply chain risks.

A diversified supplier base is crucial for minimizing the impact of supplier-related backorders. Having multiple suppliers ensures a steady supply chain and reduces vulnerability from relying on a single source.

Advantages of Selling on Backorder

Selling on backorder enhances the perceived demand for products, making them more appealing to customers. When customers see that an item is on backorder, it can create a sense of urgency and exclusivity, driving higher interest and sales.

Improved cash flow is another key benefit of selling products on backorder, as businesses can receive payment before delivering the products. This pre-payment can be good for managing financial resources and planning future inventory purchases. Additionally, selling on backorder, the space required to store the inventory, increasing available storage space, and reducing warehousing costs.

Offering items on backorder can also lead to higher product demand. Customers who are willing to wait for their desired products can help maintain continuous sales momentum, even when certain items are not immediately available. And the extended delivery expectation set with buyers provides for using less expensive shipping services because there is no immediacy built into the purchase, which drives up shipping costs (and drives down margins).

Disadvantages of Selling on Backorder

Despite its advantages, selling on backorder comes with several drawbacks. One significant disadvantage is the potential for loss of sales, as customers may seek alternatives if they are unwilling to wait for backordered items. This loss of sales can directly impact a business’s revenue.

Longer wait times for customers can lead to dissatisfaction and increase the likelihood of order cancellations. This dissatisfaction can result in a loss of customers, as they may choose to shop elsewhere in the future.

Additionally, managing backorders can increase the use of resources, as businesses need to handle customer inquiries, process refunds, and manage additional logistics.

Overall, while selling on backorder can be beneficial, businesses must be prepared to manage the challenges and potential downsides effectively.

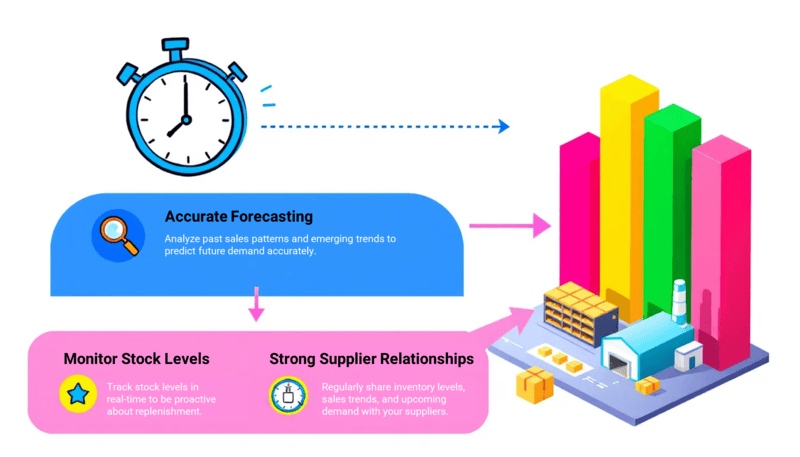

Strategies to Minimize Backorders

To minimize backorders, businesses must implement effective inventory management strategies. Accurate demand forecasting based on past sales data is essential for managing inventory and reducing backorders. Also, endeavor to maintain safety stock to ensure inventory levels can meet unexpected demand and mitigate the risk of backorders.

To minimize backorders, businesses must implement effective inventory management strategies. Accurate demand forecasting based on past sales data is essential for managing inventory and reducing backorders. Also, endeavor to maintain safety stock to ensure inventory levels can meet unexpected demand and mitigate the risk of backorders.

Setting reorder points based on historical sales data helps prevent stockouts and minimizes the likelihood of backorders. Working with multiple suppliers ensures a steady supply chain and can mitigate the risks associated with having only one supplier. Lastly, regularly check inventory levels through regular cycle counts as SKUs near depletion to minimize backorders and respond promptly to any warehouse management discrepancies.

Maintain Safety Stock

Safety stock in inventory management covers unusual demand and supplier issues. Having the right amount of safety stock optimizes inventory use and capital, preventing stockouts. A solid business strategy that keeps popular items in stock is key to minimizing backorders.

Businesses should prioritize inventory items by importance to customers to manage backorders effectively. Focusing on popular and high-demand items ensures sufficient stock to meet customer demand and avoid backorders.

Set Reorder Points

Reorder points should factor in lead times to ensure timely replenishment. Safety stock levels must also be incorporated into reorder point calculations to buffer against unexpected demand. Setting precise reorder points is essential to prevent stockouts and maintain inventory efficiency.

Combining historical data with accurate lead times and safety stock levels allows for effective reorder point settings. This approach ensures that businesses can maintain optimal inventory levels and minimize the risk of backorders.

Diversify Suppliers

Supplier diversification mitigates risks by ensuring availability during disruptions. Over-reliance on a single supplier can increase vulnerability if problems arise. Working with multiple suppliers provides options to fulfill orders, reducing the risk of backorders.

Building relationships with various suppliers can lead to better pricing and terms, further enhancing inventory management. However, vendor diversification adds complexity in management and coordination efforts, which businesses must be prepared to handle.

Customer Management During Backorders

Effective customer management during backorders is crucial for maintaining satisfaction and loyalty. Keep customers informed about delays and updates to gain their trust and engagement. Offering discounts or coupons on future orders can serve as an incentive for customers waiting for backordered items.

Shipping partial orders and waiving extra shipping charges can improve the customer experience. Automated emails can generate anticipation and maintain interest while keeping customers informed and connected to the business.

Clear Communication

Transparent communication about expected delays can significantly enhance customer trust. Provide order status updates and clarity on backorder timelines. Keeping customers informed helps manage expectations and reduce frustration and order cancellations. Regular communication ensures that customers feel valued and understood, even during delays.

Build Excitement

Regular updates on the status of backordered items can help sustain customer interest and enhance the overall shopping experience. This engagement can turn a potential negative (the wait) into a positive anticipation. Creating excitement around backordered items can also build brand loyalty and encourage customers to wait for their desired products rather than go shopping somewhere else.

Offer Alternatives

Offering alternative products allows customers to find suitable replacements that potentially fulfill a pressing need, eliminating the frustration of having to wait for the order to arrive.

Offering incentives, such as discounts or loyalty points, can encourage customers to accept backordered items or alternatives as a quid pro quo. These strategies improve customer satisfaction and loyalty, ultimately leading to positive brand perception and increased lifetime customer value.

Summary

Understanding backorders is essential for both businesses and customers. Backorders indicate that demand exceeds supply, but they allow continued sales and customer engagement even when stock is depleted. Differentiating between backorders and out-of-stock situations is necessary for effective inventory management and transparency.

By identifying and addressing the common causes of backorders, such as unusually high demand, low safety stock, and supplier issues, businesses can minimize their impact. Effective customer management during backorder situations, through clear communication, building excitement, and offering alternatives, can provide for an enjoyable customer experience and lead to a healthy, long-term relationship.

Frequently Asked Questions

What is a backorder?

A backorder is simply when you order something that’s out of stock but it will be shipped to you once it’s back in inventory. This means you might have to wait a bit, but your order is still secure!

How do backorders differ from out-of-stock items?

Backordered items can still be bought with a promise to deliver later, while out-of-stock items aren’t available for purchase at all until they are restocked. So, if you’re placing a backorder, you know it’s on its way eventually!

What are some common causes of backorders?

Backorders often happen due to unexpected spikes in demand, insufficient safety stock, and problems with suppliers. Keeping a close eye on these factors can help prevent this frustrating situation.

How can businesses minimize backorders?

To minimize backorders, focus on maintaining safety stock, accurately setting reorder points, and diversifying your suppliers. These strategies will help ensure that you have enough inventory on hand to meet demand.

What strategies can help manage customer expectations during backorders?

Managing customer expectations during backorders is all about clear communication and keeping them in the loop with regular updates. You can also offer alternative products or incentives to keep their interest piqued.